A Comprehensive Analysis of Aromatic and Aliphatic Polyurethane Flooring Services by Target Engineering in Egypt, Morocco, and the UAE

Executive Summary: The Pinnacle of Specialized Flooring Solutions

Specialized flooring is a vital component of modern infrastructure, as contemporary projects require solutions that go beyond traditional concrete to ensure performance, durability, and safety. In this context, Target Engineering, founded in 2005, stands out as a leading force in the specialized engineering sector in the Middle East and North Africa (MENA) region, particularly in flooring, waterproofing, and rehabilitation.[1, 1] The company’s scope of work extends to three key and dynamic markets: Egypt, Morocco, and the United Arab Emirates, giving it a unique strategic advantage to access a wide range of projects in the region.[1, 1]

This report provides an in-depth analysis of the flooring services offered by Target Engineering, with a specific focus on the use of aromatic and aliphatic polyurethane (PU) materials. The core of the company’s competitive advantage lies in its comprehensive approach, which is based on integrated systems. This approach is not limited to simply applying materials but extends to understanding the chemical properties of different materials and selecting the most suitable one for each project. The report also highlights the strategic partnerships of Target Engineering with reputable global suppliers such as Krypton Chemical and Sika, as well as its certification as an approved applicator for these companies, which ensures the highest standards of quality, performance, and compliance with global regulations.

This analysis aims to provide a comprehensive view of the technical and commercial advantages of polyurethane solutions, while highlighting Target Engineering’s ability to provide customized solutions that meet the precise requirements of each project, whether it is to face industrial challenges in warehouses or achieve aesthetics and durability in sun-exposed outdoor areas.

Chapter One: The Modern Necessity for Advanced Flooring Systems

1.1 The Evolving Role of Flooring in Modern Infrastructure

In modern construction projects, flooring is no longer just a surface to walk on, but has become a critical functional and engineering element that requires precise specialization. This shift is evident in the comprehensive scope of work offered by Target Engineering, which goes beyond traditional construction work to include a wide range of specialized services such as flooring, waterproofing, thermal insulation, and crack treatment.[1, 1] This diverse list of services indicates that the market is moving away from individual contracts for each service and towards a model of an integrated partner capable of addressing problems from their roots.

This approach is a key competitive advantage for Target Engineering. While a traditional contractor might focus only on applying the final layer of the floor, Target can address underlying challenges such as waterproofing or crack repair before applying the flooring layer, which ensures superior performance and longevity. This integration of multiple services reduces the overall project risks for the client and enhances the company’s position as a reliable entity that provides comprehensive solutions from start to finish. This deep understanding of the requirements of major projects, such as those mentioned in the company’s project portfolio, proves that its expertise extends beyond mere application to the planning and execution of integrated engineering systems.[1, 1]

1.2 A New Generation of Materials: The Rise of Polyurethane

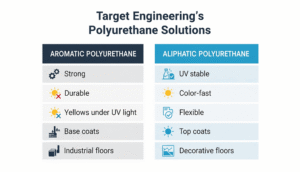

The explicit inclusion of Aromatic Polyurethane and Aliphatic Polyurethane materials in Target Engineering’s list of flooring services demonstrates its deep understanding and extensive knowledge of the different chemical properties of these materials.[1, 1] The company no longer offers just “PU floors” in general, but rather classifies its services based on the precise chemical composition of the material, allowing it to provide tailored engineering solutions to meet the unique requirements of each environment.

This specialization demonstrates a high level of technical expertise, as the final performance and lifespan of the floor depend greatly on the selection of the correct type of polyurethane. For example, a client looking for a UV-resistant floor in a rooftop car park needs a completely different solution than a client who needs a highly abrasion-resistant floor in an enclosed warehouse. By clearly distinguishing between the two types, Target Engineering demonstrates its ability to provide precise and fit-for-purpose solutions, which confirms its slogan “Specialized Engineering Works.”

Chapter Two: Target Engineering: A Foundation of Regional Excellence

2.1 Company Profile and Core Competencies

Target Engineering Specialized Works has been a major player in the Egyptian engineering sector since its establishment in 2005.[1, 1] This long history of nearly two decades in the construction sector is a strong indicator of stability, reliability, and accumulated experience. The company’s ability to survive and grow through different economic cycles proves a solid and customer-centric business model. It confirms its commitment to designing “tailored engineering solutions” for the unique requirements of each project.

Target Engineering’s extensive portfolio of work across various sectors, from industrial to commercial and residential, solidifies its position as a trusted partner. This is evident through the list of projects it has executed in prominent locations such as the New Administrative Capital, the National Museum of Egyptian Civilization, and other vital facilities in Egypt. These projects reflect the company’s ability to handle complex tasks and meet the highest technical standards, proving that the expertise mentioned in its profile is not just a claim but a documented and tangible reality.

2.2 The Geographical Triad: A Strategic Footprint in the MENA Region

Target Engineering’s geographical footprint in Cairo, Egypt, Kenitra, Morocco, and Abu Dhabi, UAE, demonstrates a clear strategic vision to capitalize on key regional markets.[1, 1] This presence is not a coincidence, but a deliberate decision aimed at leveraging the construction booms in these countries. Egypt, the UAE, and Morocco are among the fastest-growing construction markets in the region, which makes the company’s presence in these three countries a pivotal strength.

This strategy allows the company to transfer expertise and knowledge between different markets. For example, the experience gained from high-specification projects in the UAE, such as those requiring advanced flooring systems, can be applied to major projects in the New Administrative Capital in Egypt, and vice versa. This interaction allows the company to provide the best globally acquired practices and adapt them to local needs, creating a positive feedback loop of growing expertise that enhances its competitive capabilities.

2.3 Certified Expertise: The Foundation of Trust

Target Engineering’s accreditation as a certified applicator by major global companies like Sika and Krypton Chemical is a definitive testament to its technical expertise and commitment to the highest quality standards.[1, 1] This accreditation represents a certification from an independent third party that Target Engineering’s personnel are qualified and trained to apply these companies’ products in accordance with specified and rigorous technical procedures. This level of validation eliminates quality-related risks for clients and gives them an added guarantee that the work performed complies with international specifications.

This certification links the quality of Target Engineering’s service to the global reputation of the material manufacturers. It also ensures the company’s access to the latest product formulations, allowing it to offer innovative and effective solutions. These strategic partnerships with key suppliers such as Sika, Krypton, FOSROC, and MAPEI (according to the list of suppliers) [1, 1] are a fundamental pillar of the company’s business strategy, ensuring that the applied materials are of high quality and backed by manufacturer warranties.

Chapter Three: The Fine Technical Differences: Aromatic vs. Aliphatic Polyurethane Simplified

3.1 The Chemistry of Performance: An Introduction to Polyurethane

Polyurethane is known as a versatile polymer formed from a chemical reaction between a diisocyanate monomer and a hydroxyl group-containing polymer. This reaction produces a repeating urethane compound, which forms the backbone of the polymer. This polymer can be hard or flexible, depending on the nature of the components used, allowing its properties to be customized to suit different applications such as flooring, paints, and insulation.

The main differences between types of polyurethane lie in the chemical composition of the isocyanate monomer. Aromatic polyurethane is characterized by the presence of a benzene ring in its molecular structure, while aliphatic polyurethane lacks this ring. This fundamental difference in molecular structure is what determines the final properties of the product, particularly with regard to its UV resistance and long-term mechanical performance.

3.2 Aromatic Polyurethane: Strength, Durability, and Economy

Aromatic polyurethane is the ideal choice for indoor applications that require exceptional mechanical strength and high resistance to abrasion. Among the products that rely on this type, Krypton Chemical highlights Impermax QC, which is a semi-thixotropic liquid aromatic polyurethane resin known for its ability to react quickly even at low temperatures. This property makes it perfectly suitable for use during the winter and allows for a quick return to service, reducing downtime in industrial projects.

The main weakness of this type of polyurethane is its lack of UV resistance, which leads to yellowing and degradation over time when exposed to direct sunlight. For this reason, aromatic polyurethane is considered the ideal choice for enclosed, sun-unexposed areas, such as factory floors, warehouses, garages, and engine rooms, where chemical and mechanical resistance are the top priorities, while aesthetics come second.

3.3 Aliphatic Polyurethane: Timeless Aesthetics and UV Resistance

In contrast, aliphatic polyurethane is distinguished by its superior resistance to UV rays and its ability to retain its original color without yellowing or degradation. Krypton Chemical offers products like Impermax LY, which is described as having “low yellowing.” Other products from the same company, such as Colodur and Pavistone 2K UV, are specifically designed to resist UV rays, making them ideal for outdoor use.

The superior UV resistance is the crucial feature that makes aliphatic polyurethane the only choice for exposed outdoor applications. This includes building roofs, balconies, walkways, and open-air car park floors. It provides the same durability and flexibility as its aromatic counterpart, in addition to maintaining the aesthetic appearance of the floor in the long term. This clear understanding of the difference between the two types allows Target Engineering to provide suitable engineering solutions for every challenge, whether in a harsh indoor industrial environment or in an open outdoor space.

3.4 Table: Comparative Analysis of Polyurethane Flooring Systems

| Property | Aromatic PU | Aliphatic PU | |

| UV Resistance | Poor (tends to yellow and degrade over time) | Excellent (maintains color and aesthetic appearance) | |

| Chemical Resistance | Very High (used in harsh environments) | Very High (used in harsh environments) | |

| Abrasion Resistance | Excellent (withstands heavy loads and high traffic) | Excellent (withstands heavy loads and high traffic) | |

| Cost | Relatively Low | Relatively Higher (due to UV-resistant additives) | |

| Ideal Uses |

Building roofs, balconies, outdoor walkways, open-air car parks |

||

| Product Examples | Impermax QC |

|

|

Chapter Four: The Power of Partnership: Target Engineering’s Global Supplier Network

4.1 Strategic Alliances for Unmatched Quality

Target Engineering’s list of certified suppliers is not just a collection of brand names; it is a strategic mosaic that provides the company with unparalleled flexibility and the ability to choose the optimal product for every engineering challenge. These partnerships with industry leaders such as Sika, Krypton Chemical, FOSROC, and MAPEI [1, 1] give Target Engineering access to a wide-ranging product portfolio, ensuring it has the right solution for any technical or environmental requirement. A single manufacturer cannot be the best at everything, and for this reason, Target’s ability to navigate the offerings of these partners and provide the optimal solution is proof of its deep expertise.

For example, Sika is known for its focus on innovation and sustainability through technologies like Purform® that reduce the diisocyanate monomer content to increase worker safety. In contrast, MAPEI offers Mapefloor CPU systems that combine polyurethane and cement, making them ideal for facilities that require high resistance to thermal and chemical shocks, such as food and beverage plants. Target Engineering’s expertise lies in its ability to understand these fine distinctions and select the material that not only meets performance requirements but also considers aspects of safety and the environment.

4.2 Spotlight on Suppliers: Products and Applications

The partnership with global suppliers allows Target Engineering to offer a comprehensive range of specialized products for every application:

- Krypton Chemical: The company has a local factory in Egypt, which reflects its commitment to the regional market. Its products include the diverse

RaystonandImpermaxsystems, which feature both aromatic and aliphatic polyurethane. It also offers unique solutions likeRaycrete SL, a cementitious polyurethane system specifically designed for industrial applications exposed to thermal shocks. - Sika: As a global leader, Sika provides a wide range of flooring solutions under the

Sikafloorname.Sikafloorproducts are used in a variety of applications, from industrial floors that require high abrasion resistance to decorative floors for commercial environments. The company is also known for itsSikaflexproducts, which are polyurethane-based sealants used for expansion joints and connections. - MAPEI: MAPEI is a key supplier of advanced industrial flooring systems.

Mapefloor CPUsystems stand out as they combine polyurethane and cement to provide exceptional resistance to chemical agents and thermal shocks. These systems are widely used in food and beverage processing plants and laboratories, where hygiene and resistance are essential factors.

4.3 Specialized Top Coats from Krypton Chemical: Aliphatic and Polyaspartic

Krypton Chemical offers a wide range of specialized top coats that are used as a final layer to protect primary systems and provide additional properties. These coats are classified into two main types: Aliphatic and Polyaspartic, each with its unique properties and applications.

- Aliphatic Top Coats:

- Properties: These systems are characterized by their superior resistance to UV rays and their ability to retain color without yellowing or degradation. They also provide excellent resistance to abrasion and chemicals. A prominent product in this category is

COLODUR, a one-component aliphatic polyurethane resin used as a protective top coat for waterproofing membranes. - Uses: These coats are applied to outdoor surfaces such as building roofs, balconies, and stadium terraces that are exposed to heavy pedestrian or light vehicular traffic.

Additional Links: For more information on Krypton Chemical’s products, please visit the official parent company website or the official website in Egypt.

- Properties: These systems are characterized by their superior resistance to UV rays and their ability to retain color without yellowing or degradation. They also provide excellent resistance to abrasion and chemicals. A prominent product in this category is

- Polyaspartic Systems:

- Properties: Polyaspartic systems, such as

KRYPTANATE 100andKRYPTANATE M, are fast-curing two-component systems. Unlike traditional polyurea systems, they have a slow enough curing time to allow for manual application with a roller or spreader. These systems provide high resistance to abrasion and corrosion, excellent UV resistance, and superior gloss retention. - Uses: These systems are used for industrial, marine, and architectural solutions, as well as top coats in flexible and comfortable flooring systems.

- Properties: Polyaspartic systems, such as

Chapter Five: A Portfolio of Success: Proven Regional Expertise

5.1 Delivering on Promises: A Showcase of the Company’s Projects

Target Engineering’s project portfolio is the best evidence of the company’s capability and efficiency in executing large and complex projects in the MENA region. The list includes prominent projects in Egypt, such as the New Administrative Capital project, New Alamein Towers, and Cairo Festival City Mall.[1, 1] The size and scope of these projects demonstrate the company’s immense logistical and technical capacity to manage large-scale execution tasks. The recurring mention of “Iconic Tower” and “Capital Business District” in the project list also indicates client trust and long-term working relationships.

These projects not only show Target Engineering’s ability to handle major challenges but also confirm its expertise in using specialized materials. For example, it appears in the projects executed at Aeon Towers Mall of Arabia that the company used epoxy flooring in the car parks. This confirms that the company’s specialized flooring services are not just theoretical offerings but are an essential and proven part of its work.

5.2 Project Data: A Quantitative Record of Achievement

The quantitative data for Target Engineering’s projects provide tangible evidence of its experience in handling various types of specialized flooring. The following list shows some projects where epoxy and polyurethane were used, with a breakdown of the quantities of work performed, which enhances the company’s credibility with potential clients:

| Project Name | Contractor/Client | Material Used | Value/Quantity Executed |

| Cairo Airport Garage | El Nile for Roads and bridges | Epoxy Flooring | 130,000 m² |

| Cook Door Factory | Perfect Company | Epoxy Flooring | 5,500 m² |

| Children’s Cancer Hospital (57357) | ECC Company | Epoxy Flooring | 1,800 m² |

Clarion Factory |

Owner | Epoxy Flooring | 9,000 m² |

| Faw Industrial Group Factory | Faw Industrial Group | Epoxy Flooring | 3,000 m² |

Conclusion: The Future of Specialized Engineering in the MENA Region

This analysis proves that Target Engineering is not just a regular contractor but a specialized engineering partner that provides real added value through its comprehensive approach and deep technical expertise. Its strategic location in Egypt, Morocco, and the UAE, along with its proven track record of major projects and its certified partnerships with global leaders like Krypton Chemical, Sika, and MAPEI, places it at the forefront of companies that offer advanced polyurethane flooring solutions.

Target Engineering’s ability to distinguish between aromatic and aliphatic polyurethane types and provide the right solution for each environment, whether a harsh industrial one or an exposed outdoor one, demonstrates its complete understanding of market requirements. This advantage is a vital factor in making engineering decisions.

In conclusion, Target Engineering is the ideal partner for any future project that requires sophisticated, high-performance flooring solutions in the region, as it offers a unique blend of local expertise, global standards, and a commitment to quality that ensures the highest levels of performance and durability.

Contact Our Regional Engineering Teams

UAE Operations

Dar Al-Salam Bldg., Al-Danah, Abu Dhabi

+971 506 330 462 | uae@targetsw-eg.com

Egypt Headquarters

48 El-Horreya St., Heliopolis, Cairo

+202 2417 8704 | admin@targetsw-eg.com

Morocco Branch

IMM. 402 ALLIANCE DARNA TRANCHE 2, Kenitra

+212 663 782812 | maroc@targetsw-eg.com

No comment